2012: Product Capacity Manufacturing Management

Commodity Production Management

When a product reaches high volumes and above average margins it will over time invite competitors into the market. When this happens, competitive pressures will gradually erode the profitability the product contributes to the company’s bottom line. When a product reaches commodity status a manufacturer is faced with making one of the following decisions:

1) Stop making the no margin to negative product to free the available production time to manufacture products that are still within the profit contribution life-cycle

2) Continue producing the product and fine-tune the process to find and apply productivity enhancements while adding new equipment to service the production schedule for news more profitable products

3) Develop a manufacturing relationship with a low cost offshore manufacturer to produce the commodity product on the company’s behalf. This strategy can enhance the commodity products contribution to the company’s bottom line, improve customer service levels, and free up production capacity for products that are in the growth mode of the lifestyle in sales and profitability.

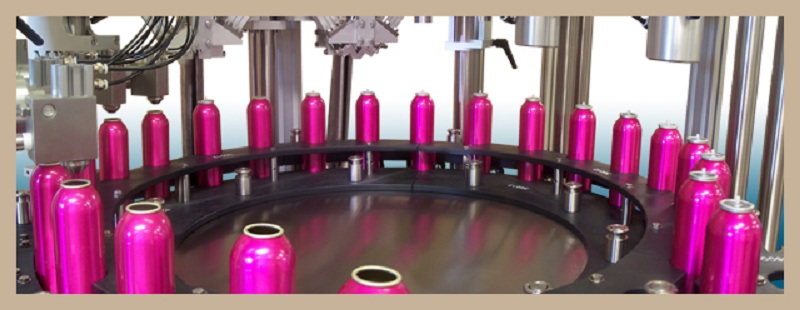

Project: Offshore Aerosol Product Filling

Executive on Demand Position:

President, Chief Operating Officer, Vice President Sales and Marketing, Vice President Procurement

Project Outline:

A major North American filler has been very successful in capturing a high market share of the low cost high volume private brand aerosol products market. In doing so it’s filling facilities operate must continuously be searching the market for lower cost product components and implement productivity and efficiency measures within the production facility.

With the filling business continuously growing, it became very evident that the company needed to re-evaluate its manufacturing priorities to best meet the company’s sales and production goals. I Having actively pursued and implemented a global procurement strategy for component materials, it became necessary to review the company’s need to either invest in new filling reduction equipment to meet the customer supply requirements or to pursue an offshore supply partnership to produce and supply the low margin group of products and refocus the current filling equipment to high volume products with an enhanced profit margin. This approach allows the company to meet the needs of its customers: maintaining low prices, maintaining supply commitments, grow production capacity and most importantly enhance the bottom line contribution.

Project Outcome:

A search was conducted offshore for low cost aerosol filling operations. Several potential filling operations were identified during the month of April. A production facility pre-qualification trip has been scheduled for early May as well a secondary trip is for mid-June 2012 to finalize the potential production relationship for the high volume/low margin commodity aerosol filled products.