2012: Skirt Aerosol Cap

Project Outline:

Tinplate Aeros![]() ol Can Manufacturing History:

ol Can Manufacturing History:

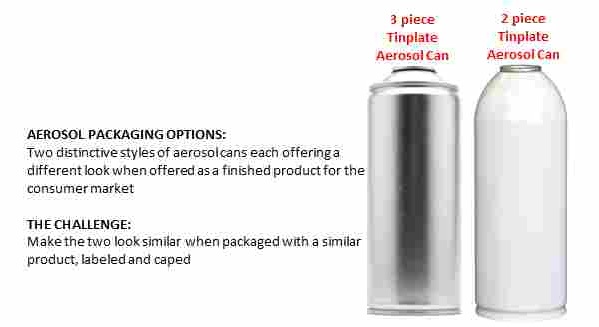

The aerosol can manufacturing industry has in itself gone through several design changes to enhance the look and the safety of aerosol packaged products. The first generation of aerosol cans were of a straight wall design. This is a three piece design aerosol can consisting of a top dome, bottom plate and welded body. It has an industrial look to it and continues to be the popular aerosol products packaged of choice for the industrial market.

The second generation of aerosol can design consist of styling the top of the can by shifting the top dome crimping area to an area that is covered by the over-cap. This aerosol can design is also a three piece can and is referred to as a necked-in can. By moving the crimp area inside the over-cap the look of the can when it is a finished product has a more stylish and clean look to it. This can quickly became the can of choice in the manufacture of consumer related aerosol products.

The third generation of aerosol cans are manufactured using only two components. The can consists of a formed body that includes the top dome as the first piece. The second component is![]() a bottom plate which is crimped into place. The forming of the tinplate body is a technology borrowed from the aluminum aerosol can forming industry. This can was originally almost extensively used to package refrigerant product used to recharge refrigerators, freezers and vehicle air conditioning systems. The can is designed to handle higher pressures and is significantly more expensive than the three piece aerosol can. The two piece can was subsequently adapted and manufactured more economically to compete with the traditional straight wall and necked-in aerosol can manufacturers. This new design two piece formed can provides a premium look to a product without a significant cost change to the fillers.

a bottom plate which is crimped into place. The forming of the tinplate body is a technology borrowed from the aluminum aerosol can forming industry. This can was originally almost extensively used to package refrigerant product used to recharge refrigerators, freezers and vehicle air conditioning systems. The can is designed to handle higher pressures and is significantly more expensive than the three piece aerosol can. The two piece can was subsequently adapted and manufactured more economically to compete with the traditional straight wall and necked-in aerosol can manufacturers. This new design two piece formed can provides a premium look to a product without a significant cost change to the fillers.

Challenge:

From ![]() a consumer retailing perspective the 2 piece stamped aerosol can is the preferred model. It’s appearance is higher end and trending but the customers pays a premium for using it. The are many market channels where an aerosol product category has become a commodity that the price a filler can get for producing the product is done at little to no margin. Changing the aerosol can from an existing 3 piece model to a 2 piece model adds cost thus causing margin erosion. This issue presents a new opportunity. Why not develop an aerosol cap that can make the current economical and most widely used aerosol can and, the 3 piece necked-in can look like a 2 piece can when it is a finished product. This can be achieved by designing a unique aerosol cap that not only protect the valuing device but have this cap contribute to the style of the can to enhance the look of the finished product that when on a retailers shelf.

a consumer retailing perspective the 2 piece stamped aerosol can is the preferred model. It’s appearance is higher end and trending but the customers pays a premium for using it. The are many market channels where an aerosol product category has become a commodity that the price a filler can get for producing the product is done at little to no margin. Changing the aerosol can from an existing 3 piece model to a 2 piece model adds cost thus causing margin erosion. This issue presents a new opportunity. Why not develop an aerosol cap that can make the current economical and most widely used aerosol can and, the 3 piece necked-in can look like a 2 piece can when it is a finished product. This can be achieved by designing a unique aerosol cap that not only protect the valuing device but have this cap contribute to the style of the can to enhance the look of the finished product that when on a retailers shelf.

Solution:

The most popular cap size is the one that fits a 211/65D aerosol can. To create a family of caps it is important to also include in the design a cap for the 205/52D aerosol can. A 211/65D cap concept was developed using children’s plast ercine and forwarded to a CAD-CAM designer or about July 15th. Several days later technical drawings were received along with a 3D PDF so that the cap concept could be shared with companies that we know have expressed an interest in the idea. Based on the 3D drawings, significant interest and support has been created. The design concept borrows an idea from other steps caps that I have done in the past. The step shape to the aerosol skirt concept to the will enable the manufacturer to stack the caps when boxed to enhance shipping efficiency which is estimated at 30% greater than the standard 211/65D and 202/52D aerosol caps.

ercine and forwarded to a CAD-CAM designer or about July 15th. Several days later technical drawings were received along with a 3D PDF so that the cap concept could be shared with companies that we know have expressed an interest in the idea. Based on the 3D drawings, significant interest and support has been created. The design concept borrows an idea from other steps caps that I have done in the past. The step shape to the aerosol skirt concept to the will enable the manufacturer to stack the caps when boxed to enhance shipping efficiency which is estimated at 30% greater than the standard 211/65D and 202/52D aerosol caps.