2006: Aerosol Containerization and Landed Cost Simulator

AEROSOL CONTAINERIZATION and LANDED COST SIMULATOR

Executive on Demand Position:

TBA

Project Outline:

TBA

Project Outcome:

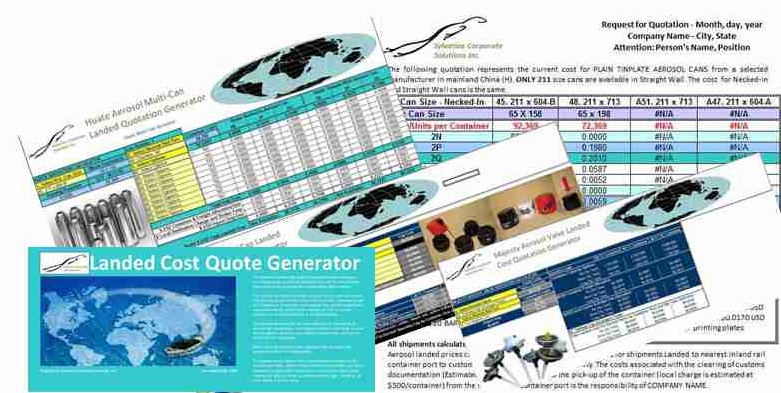

Purchasing aerosol cans from a global supplier requires an that a buyer understand the difference in landed cost associated from using different size of containers (20, 40, 40 high cube, 45 foot). Optimizing the space is critical in keeping the shipping value as low as possible. A major advantage to procuring aerosol cans from Asia other than per unit cost is that minimum order quantities (MOQ’s) are set significantly lower than those from North American manufacturers. This can provide a cot advantage especially to a small to medium sized enterprise (SME) such as an aerosol can filler. It is common in North America for aerosol can makers to have MOQ’s of 100,000 cans for any pre-printed cans with a premium cost if an MOQ is 50,000 units. In Asia the MOQ is set at 10,000 units and the container can be mixed with more than one pre-printed can product and in different size

configurations.

The buyer at the aerosol can filling company did not have the tools available to easily calculate the best order and container size required to deliver the most cost effective aerosol can to the manufacturing facility. A program was created using MS Office Excel that included the necessary variables using drop boxes for each of the pre-printed aerosol can products manufactured in the Asia facility and it included the flexibility to mix different can sizes.

The lower MOQ’s and the ability to mix can sizes permitted the buyer to apply the lowest per unit cost for the aerosol cans. This resulted in better managed inventory levels that met with planned production requirements based on customer ordering patterns and lower inventory storage requirements.