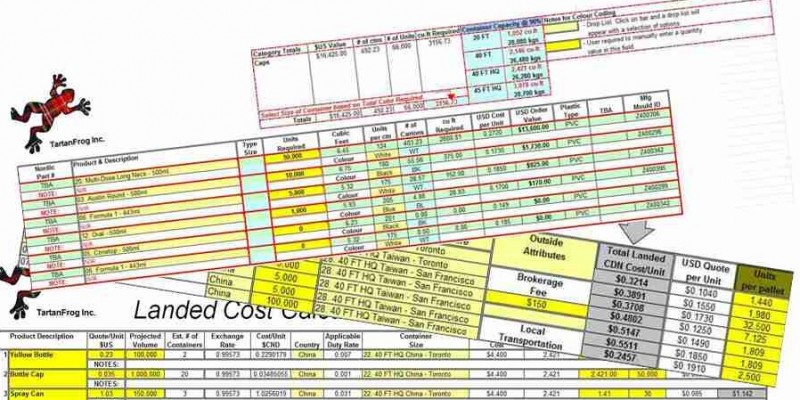

2006: Bottle Containerization and Landed Cost Simulator

BOTTLE CONTAINERIZATION and LANDED COST SIMULATOR

Executive on Demand Position:

TBA

Project Outline:

TBA

Project Outcome:

Working with small to medium sized enterprises (SME’s) it became clear very early that many tools that I took for granted in a major corporate environment did not exist or were not very well understood by the organizations. The lack of understanding in properly assessing the landed cost of a product procured offshore or the inability to accurately estimate the quantity of product that could be packaged into a shipping container are major reasons for SME’s not considering entering the global market for

materials to enhance their competitiveness.

A major advantage of purchasing from Asia is the flexibility of the suppliers to offer minimum order quantities (MOQ’s) that are significantly lower for a product than that offered by a local supplier. In the plastics industry it is common practice in North America to institute a MOQ requirement at 100,000 and then another lower at a 50,000 unit level with a premium assessed to cost. In Asia, a single price is negotiated and the MOQ can be as low as 5,000 units. In addition, a premium price is added for colour differentiation in North America and in Asia this does not apply. As a result the North American MOQ applies to each colour, thus forcing customers to order quantities that create inventory accumulation. As for production in Asia, the customer can utilize the MOQ of 5,000 as the base and order as necessary without the need for a surcharge or excess inventory build-up.

Once an SME becomes involved in the global product procurement market, they quickly realize that the market provides for new sales opportunities and challenges. The most important challenge to be addressed was the need to help the buyer create product purchase orders to optimize the space is any required container. The buyer has the option of purchasing products to be packed and shipped using 20, 40, 40 high cube and 45 foot containers. The container size selected yield increasing cubic space availability and with this comes lower shipping costs. Add to this the complexity of having the container hand packed or pallet packed increases the potential for costly errors in calculating optimized shipping costs.

To assist an SME client an MS Office program was developed to help a buyer build a container of product using the following variables:

- different plastic materials and shapes of bottles

- different sizes of bottles

- different colours of bottles

The program enabled the buyer to easily build a purchase order for bottles in the type, quantity and colour to meet production requirements on a timely basis. The ability to order product quantities to meet customer production requirements enabled the buyer to have products manufactured and shipped in the most cost effective container required as well as reducing extra inventory to support future production.