2007: Mallethead

STEEL HAMMER TO MALLET HEAD CONVERSION SYSTEM

Executive on Demand Position:

TBA

Project Outline:

TBA

Project Outcome:

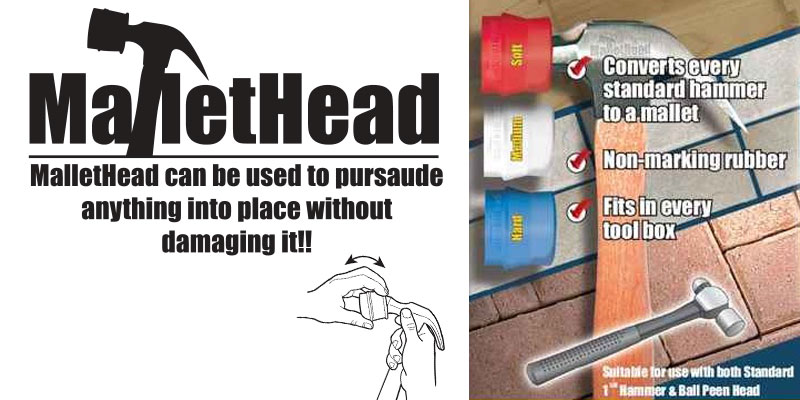

Mallethead is a unique rubber head that easily attaches to any conventional hammer and turn it into one of three different type of rubber mallets. It was invented by a Canadian that worked diligently with the local manufacturing community to produce his new idea. He had handmade prototype products to show prospective customers in Canada and the United States (Canadian Tire, Home Depot, Home Hardware, Home Shopping Channel) and based on their interest and feedback, he proceeded to take the product to the next level. Several years later and tens of thousands of dollars later he became disenchanted with the Canadian manufacturing industry. He had accumulated debt, had not been able to move from a prototype to manufacturing mould without incurring additional significant debt and if he proceeded he was still one year away from being able to produce a finished product. Secondly, based on the cost of locally producing the individual Mallethead attachments the costs exceeded the expected market price point as bench marked against traditional rubber mallets. Lastly, the local prohibitive manufacturing cost made it impossible to meet the profitability expectations for his company and his potential customers.

The owner of the company was familiar with my activities and sought assistance validating the potential of his product in the market as well as to my thoughts on having his patented invention manufactured in Asia. With my assistance he was encouraged to travel to specific areas of China that I identified as specialists in the manufacture of rubber moulded products. A trip was planned and several manufacturers were visited and asked to prepare a quotation for a packaged finished product (packaging design was complete and provided to the potential vendors) that would be retail market ready. The identified vendors were provided an engineering drawing of the product and were given a week to deliver their program. Within the week all potential vendors had submitted a quotation for the multi-cavity rubber injection mould that would be required to produce the product and the cost of making the product fully packaged in the requested four colour art design. Most importantly, all of the suppliers had produced in this short time at no cost to my client a prototype rubber injection mould, actual Mallethead hammer attachment samples in the three different colours and hardness’ as specified in the engineering drawings and to cap it all off most of them had created the retail clamshell and label required to package the product. All this delivered to his hotel prior to returning to Canada.

The experience was overwhelming for the inventor. In North America he had spent several years working with mould and production manufacturers and was not able to get the project beyond the prototype level. In China this level was exceeded in less than a week and the most impressive delivery to my client was in the costing of the finished product in a retail type clamshell package at a landed cost that he was not expecting. As a result the Canadian inventor contracted one of the manufacturers to be his supplier. The inventor quickly returned to North America and put into motion the sales and marketing plan to successfully launch the product. The product became an award winner at the largest hardware trade show in North America, became one of the hottest new tools in the do-it yourself market and most of the retailer s that had been contacted during the development phase added to the product to their tool assortment.