2007: Multi-Dose Ball Plug

RE-ENGINEERING MULTI-DOSE BOTTLE RESERVOIR PLUG

Executive on Demand Position:

TBA

Project Outline:

TBA

Project Outcome:

The optimum output of a bottle filling line is regulated to run at the maximum speed of the slowest process in the manufacture of the finished product. The basic production process for creating a finished bottle product requires that bottles be put on the line, filled, labeled, capped, heat sealed, boxed and placed on a pallet. The packing and sealing of liquid product in a multi-dose bottle requires an extra step. This step involves the use of a specialized piece of equipment to insert and plug the top reservoir from the bottle main chamber. The complexity of the process requires that the line speed be reduced by 50% in order that the plug be properly and securely inserted into the bottle.

A bottle filling client contacted me to assist in working out a solution that would allow this specialized package to run at the same speed as the remaining bottle fill equipment. The range and types of multi-dose bottles had been expanded as well as to the number of products that they could package and sell in this container was growing at a rapid rate. A review of the process verified that the speed of the current plug process equipment for the multi-dose bottle could not be changed. The result was to develop an alternative method of placing a plug in the reservoir hole. The system must be suitable to the current bottle fill line and have the flexibility to surpass the current line feed speed.

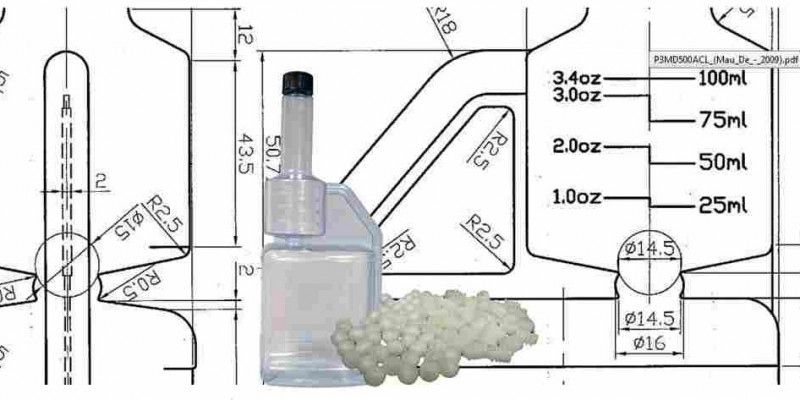

The solution to the challenge was to change the design of the plug away from a flared plug to a ball design. The reason for this was that the flared plug required a small stoppage in the line to insert the plug and push it into place. The new ball design required a small change in the design of the plug seat in the bottle. The equipment required could now be a rotating table with multiple push to seat rods to secure the upper reservoir from the bottom chamber. The add the ball it needed only to be dropped into the bottle and because of the angle sides of the reservoir, the ball plug self centered and positioned itself automatically to meet the push rod that secured it in place.

The benefits to changing the design of the seal required between the upper and lower chambers of the multi-dose bottle design enabled the client to increase the production capability of the factory without adding any significant costs. Most importantly, the speed at which the ball plug could be inserted and sealed was much greater than the current flared plug system and this provided added assurance that any future changes in equipment to enhance the productivity of the current line would not be limited by the new ball plug and insert equipment. This was very important to the client as the multi-dose bottle family had grown from two sizes in available only in a single style to four different sizes and in two different bottle styles.