Procurement: Implementing a Strategic Materials Supply Strategy for Manufacturers

Implementing A Strategic Procurement Plan for Manufacturing Materials Can Deliver Exceptional Savings

Implementing a global procurement materials strategy in any manufacturing business can yield cost savings to the company that can be applied directly to its bottom line results or when necessary be utilized to enhance its competitiveness by sharing part or all of the savings with its customers. Most procurement managers do this very well however additional savings can be achieved by implementing a process driven procurement strategy. The implementation of this type of strategy is more complex as it requires the cooperation of many areas of a company – production, engineering, sales, marketing and senior management.

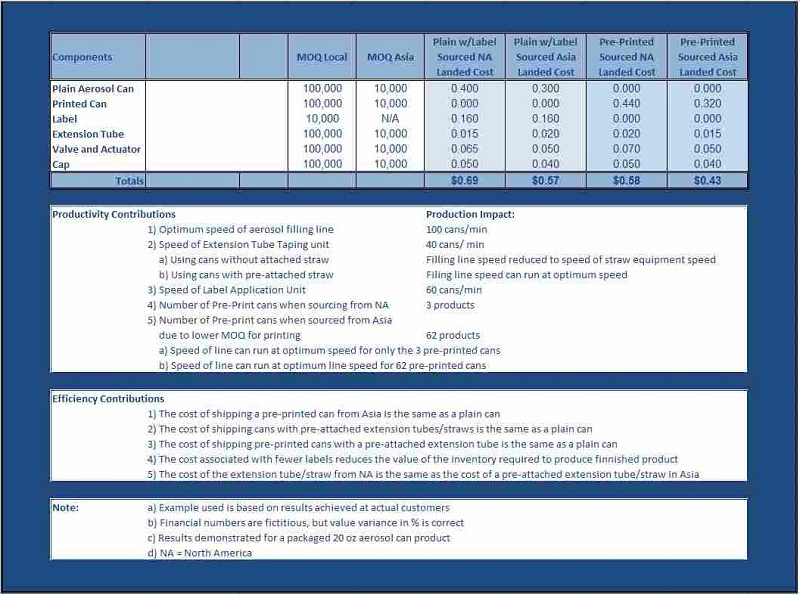

A process driven procurement strategy looks at the total process used in the manufacture of a customers product(s). Taking this approach ensures that all areas that impact the cost of making a product is reviewed and evaluated as to its need and the cost associated with each step of the process. In the example provided, I have demonstrated the additional cost savings opportunities available through the implementation of a strategic materials procurement plan. The example utilized is that of an aerosol product manufacturer making a 20 oz can of any product. The example focuses only on the costing of all the components to make a finished product. It compares the sourcing of products locally (North America) and from Asia. All costs include the logistical and import fees associated with landing the materials into inventory. The values used are fictitious, but the percentage variances are real.

Based on the example in the chart above, you can see for yourself the range of opportunities that can be achieved by implementing a part or a total strategic procurement plan. This is a complex process and requires a buy-in from all areas impacted in the manufacturing process because there may be a need to change the way some things are done. Sourcing a plain 20 oz aerosol can ONLY from an Asian source delivers a cost savings of $0.10 USD per unit (25% reduction) and for a pre-printed aerosol can the cost savings is equal to $0.12 USD per unit (23% reduction). However the implementation of a strategic materials sourcing strategy for a company operating an aerosol filling line the total potential savings achieved is equivalent to $0.26 USD per unit (62% reduction). The 62% reduction is calculated based on the costs based on sourcing and manufacturing $0.69 USD per unit and then implementing all productivity related procurement strategies yielding additional the additional savings contribution. It is important to note that a list of productivity and efficiency contributions have been added to the chart but the financial values have not been included.