Procurement: Fun with Procurement Math!

Manufacturing and selling products that have reached the peak of their market repositions the products into a class of products usually referred to as “commodities”. This usually means that the market for this category of products is saturated and any growth potential for increasing sales is usually achieved at the expense of a competitor’s product or brand. When a product is classified as a commodity it usually means that the selling price has peaked and that the ability to pass on any cost increases to customers is very difficult. At this stage of a product cycle a company will absorb the cost increase and absorb the loss by reducing the expected margin in order to keep the customers and sales it currently enjoys.

A manufacturer should always be evaluating their materials suppliers and markets to ensure that they can obtain their production materials needs at the best possible cost at all times. In a product growth market a manufacturer’s materials procurement office delivers a market competitive materials cost structure for its production facility. In a saturated market, the ability to generate sales and profit growth is much more difficult. In a saturated commoditized marketplace it is strategically important that manufacturer explore and take advantage of the global market for the supply of materials. Evaluating and qualifying global materials suppliers early in a product cycle ensures that a manufacturer can always maintain an ongoing competitive product supply to its customers.

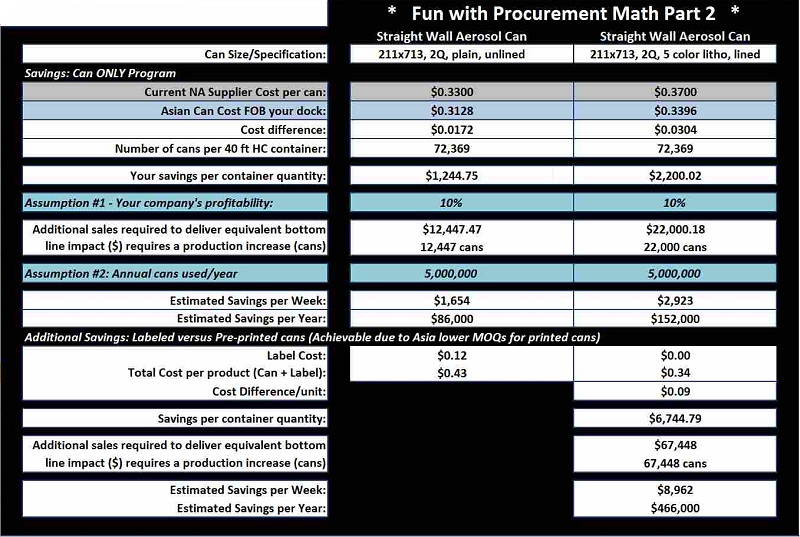

The “Fun with Procurement Math” chart is an exercise that puts into perspective the importance in delivering ongoing material costs reductions. The financial value of any cost reduction is almost 100% delivered to a company’s bottom line. Delivering the same level of value in finished product sales usually requires a significant product sales increase as the selling price must be reduced and in turn the profit generated per unit is also reduced. The chart above shows how a small cost decrease can deliver to a company the following benefits:

- Potential for increased production and sales

- Lower manufacturing costs

- Enhanced profitability

A manufacturer that has pursued and implemented successfully a global materials procurement program in their company and with this they can use the cost reduction contributions to profit to deliver anyone one or more of the following:

- Lower cost to customers to grow volume and market share at the expense of a competitor

- Offset any new costs associated with the hiring of specialized procurement and logistics personnel

- Invest in new and more productive manufacturing equipment to deliver added volume and capacity

- Invest in product R & D to add new products to diversify the company’s product assortment to increase its potential to grow its business and reduce its dependency on commoditized products